DSI Adder Snake, Low Angles to High Angles and Back with No Transfers

Location: Docks, storage sheds, long overland systemsChallenge: Economically and cleanly elevate material at some point along a mostly conventional-angle conveyor system

Solution: The DSI Adder Snake (patent pending)

Scope: Limited only by available conveyor equipment

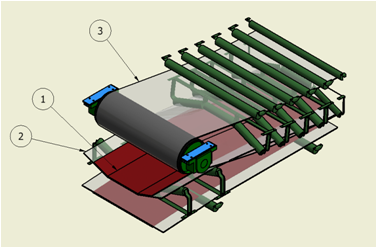

Figure 1: Complete Adder Snake Arrangement

Figure 2: Sandwich conveyor fed by low-lift tripper

Sandwich belt high angle conveyors have long been known as the best solution for tight spaces where a steep lift is required to maintain a small footprint. However, applications are also quite common in which a large footprint is available, but a high angle is needed in just a small portion of the conveyor path. Because a sandwich belt system uses a wider belt to achieve the same conveying rate as a conventional conveyor at the same speed, in an application such as that described above, the question must be asked: Should you extend the tail of the sandwich belt, or should you break up the path into two separate conveyors, in which a narrow conventional conveyor discharges on to the wider Sandwich belt system?

For instance, a tripper may travel horizontally along the length of a dock to feed a perpendicular shiploader. In cases where the shiploader is at a considerably higher elevation than the dock conveyor, a standard tripper would require that the dock conveyor and dock be much longer than otherwise necessary, as its uplift would extend quite far back from its discharge pulley. Historically, the solution in this case would be to design

Figure 3: Adder Snake sandwich entrance

The DSI Adder Snake (see Figure 1 and Figure 3), which is currently patent pending, solves the problem by swallowing the narrower conventional belt (Item 1), along with its material, into the two wider sandwich belts (Items 2 and 3). This allows the material to enter the sandwich belts with minimal disturbance and without the energy loss and additional equipment required for a standard transfer.